Coffee : small-scale processing

Practical Action

These can be manually operated but larger

scale units are normally fitted with a motor.

Disc pulpers

The same concept is involved with the disc

pulper except that the pulp is removed using

abrasion by a rough disc.

Mucilage removal The amorphous gel of

mucilage around the bean consists of

hemicelluloses, pectic substances and

sugars and is insoluble in water. This

mucilage can be removed by chemical

methods or warm water but, for small-scale

units, the only feasible method is

fermentation. Fermentation involves the

beans being placed in plastic buckets or

tanks and left until the mucilage has been

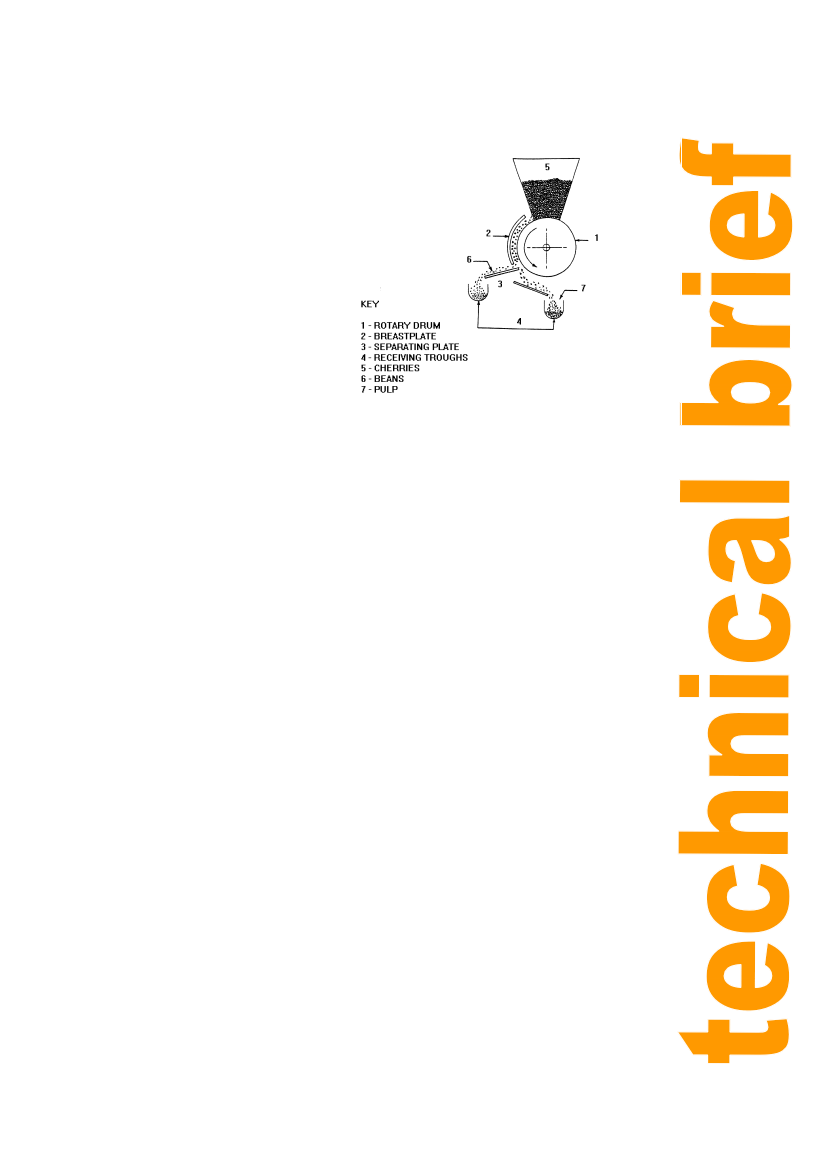

Figure 3 : Separation of pulp and beans

broken down by natural enzymes and

bacteria. The coffee should be stirred occasionally and every so often a handful of beans

should be tested by washing them in water. If the mucilage can be washed off and the beans

feel gritty rather than slippery, the beans are ready.

Drying The beans should then be washed and dried immediately to prevent spoilage and

the development of off-flavours. To prevent cracking the coffee beans should be dried slowly

to 10% moisture content (calculated on a wet-basis) using the same drying methods

described above.

Hulling and cleaning After drying the coffee should be rested for 8 hours in a well

ventilated place. The thin parchment around the coffee is removed either by hand, in a

pestle and mortar or in a small huller. The hulled coffee is cleaned by winnowing.

Roasting and Grading

The final flavour of the coffee is heavily dependant on how the beans are roasted. Roasting is

a time- and temperature-dependant process. The roasting temperature needs to be about

200ºC.

The degree of roast is usually assessed visually. One method is to watch the thin white line

between the two sides of the bean, when this starts to go brown the coffee is ready. As

preferences vary considerably from region to region, the locally-acceptable degree of roast will

need to be assessed.

Coffee beans can be roasted in a saucepan as long as they are continually stirred. A small

improvement is made by roasting the coffee in sand, as this provides a more even heat.

A roaster will produce a higher quality product. The simplest roaster is basically a tin can

with a handle so that it can be rotated slowly over a fire. There are various other roasters

suitable for larger scale units.

Coffee is graded by size, shape, odour, density and colour.

Grinding

It is easy to assess the quality of whole coffee beans. However, ground coffee beans produce

a brown powder which can be easily adulterated. Because of this there is often market

resistance to ground coffee. This market resistance can only be overcome by consistently

3